Solutions for

lithium-ion battery

Daikin has developed to market innovative solutions

to improve life cycle, safety, and high efficiency of lithium-ion battery.

The fluoromaterials are used in lithium-ion batteries, and high-performance materials are increasingly

required to meet the needs for high capacity, safety, and long life.

Daikin has developed various fluoromaterials for lithium-ion batteries.

We are also focusing on the development of next-generation batteries, contributing to next-generation

lithium-ion batteries and all-solid-state batteries.

Gasket material

Gasket material

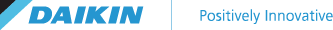

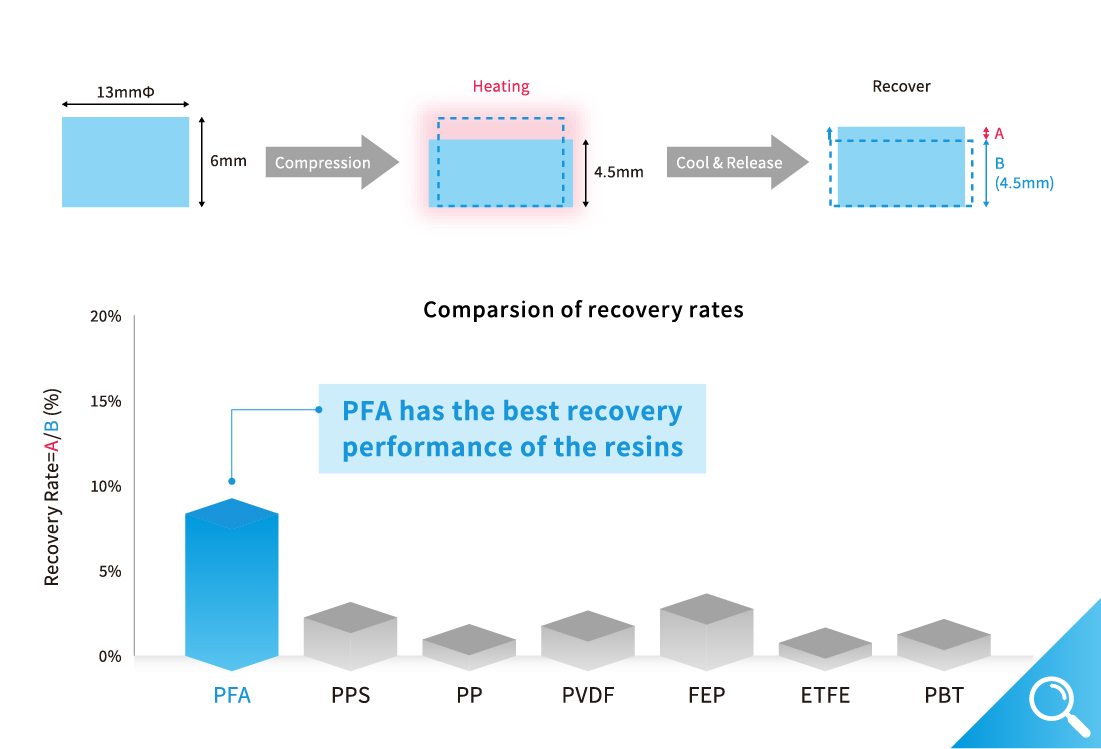

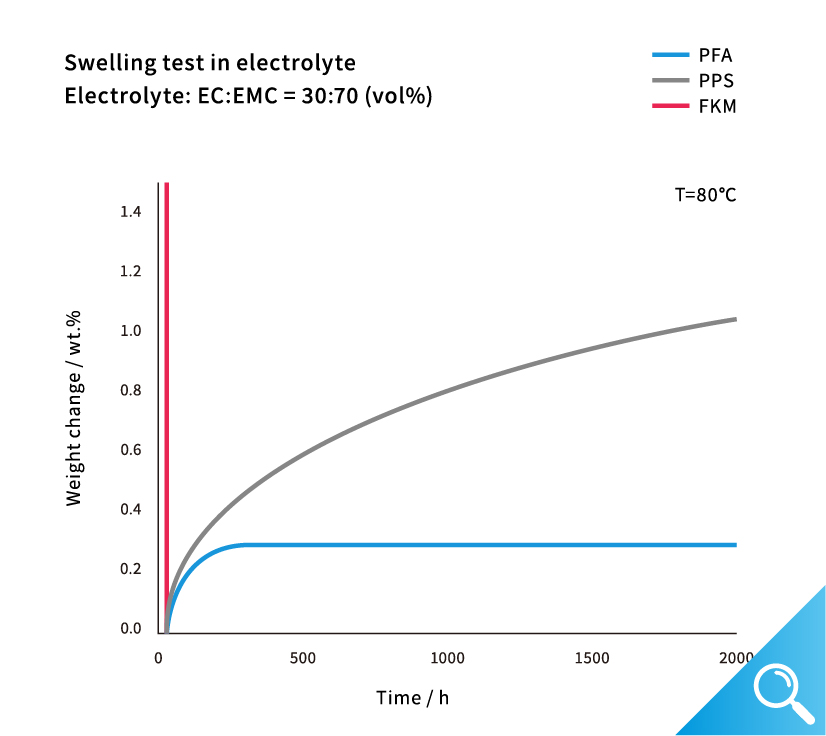

NEOFLON PFA is the best suited gasket material for long term use in lithium-ion batteries due to the excellent sealing performance, electrolyte resistance, and moisture barrier.

Cathode binder

Cathode binder

NEOFLON VT-475 contributes to high energy density electrode for a new lithium-ion battery design.

Cathode binder with SWCNT

Cathode binder with SWCNT

NEOFLON VTD-475N can increase the electric conductivity with small dosage of CNT, and then, increase the energy density.

Cathode binder for dry process

Cathode binder for dry process

POLYFLON BDP binder is suitable for dry process which is cost effective and eco-friendly.

Electrolyte additives & solvents

Electrolyte additives & solvents

Daikin electrolyte additives & solvents are suitable for long life / Si anode / high voltage / safety application.

Gasket material

Fluoropolymers for gasket materials

NEOFLON PFA is the best suited gasket material for long term use in

lithium-ion batteries due to the excellent sealing performance,

electrolyte resistance, and moisture barrier.

Cathode binder

NEOFLON VT-475

NEOFLON VT-475 is an additive of PVdF binder for lithium-ion battery

and it contributes to high energy density electrode for a new lithium-ion

battery design.

VT-475 improves fluidity decrease of the slurry at coating process. Especially high nickel-based active materials such as NMC811 and NCA, VT-475 added PVdF shows significant improvement at coating process.

NEOFLON VT-475 binder produces high density (higher than 3.6 g/cc) and thick electrodes (higher than 30 mg/cm2) with no cracking up winding. It enables high energy density electrodes.

Slurry stability

Homo or

Modified PVdF

Poor flow

NEOFLON VT-475 with

homo PVdF

Optimal flow

Flexibility (Mandrel test, Φ2mm results, after 180° wounded)

Homo or

Modified PVdF

Cracked completely

NEOFLON VT-475 with

homo PVdF

Wounded w/o cracking

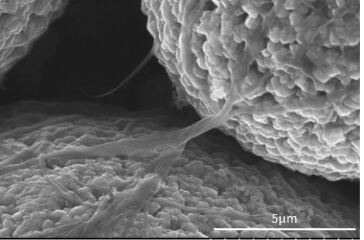

Cathode binder with SWCNT

NEOFLON VTD-475N (under development)

NEOFLON VTD-475N is a NMP dispersion which includes NEOFLON

VT-475 and TUBALL.

It can increase the electric conductivity with small dosage of CNT,

and then, increase the energy density.

NEOFLON VT-475

- ・Increase the energy density

- ・Flexibility

- ・Slurry stability

SWCNT (TUBALL)

- ・Higher adhesion

- ・Higher electric conductivity

- ・Increase the energy density (higher active material amount)

Cathode formulation example

Conventional Active material / CB / Binder = 97 / 1.5 / 1.5 (wt%)

Active material / CB / Binder = 97 / 1.5 / 1.5 (wt%)

NewActive material / TUBALL / CB / Binder = 98.52 / 0.08 / 0.4 / 1.0 (wt%)

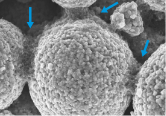

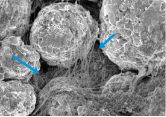

Cathode SEM image of NEOFLON VTD-475N

(VT-475 with TUBALL)

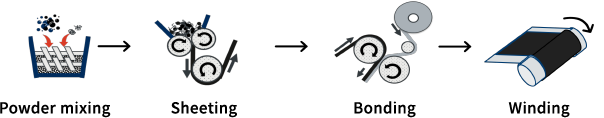

Cathode binder for dry process

POLYFLON BDP (under development)

Current wet process for making the cathode needs to make the slurry

and heat-up. If the dry process is applied, it’s cost effective and

eco-friendly because of NMP free.

POLYFLON BDP binder is suitable for this dry process of conventional

lithium-ion battery as well as all-solid-state battery.

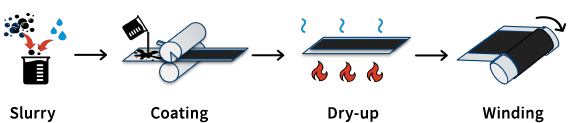

Wet process

Dry process

Electrolyte additives & solvents

SLFE1508 (under development)

Daikin fluoro ether SLFE1508 has excellent oxidation resistance

and no flash point.

The electrolyte with SLFE1508 can improve the battery

performance for Si anode.

Excellent oxidation resistance and safety performance

SLFE1508 gives higher oxidation resistance to electrolyte.

SLFE1508 also has no flash point, therefore it can increase the electrolyte flash point.

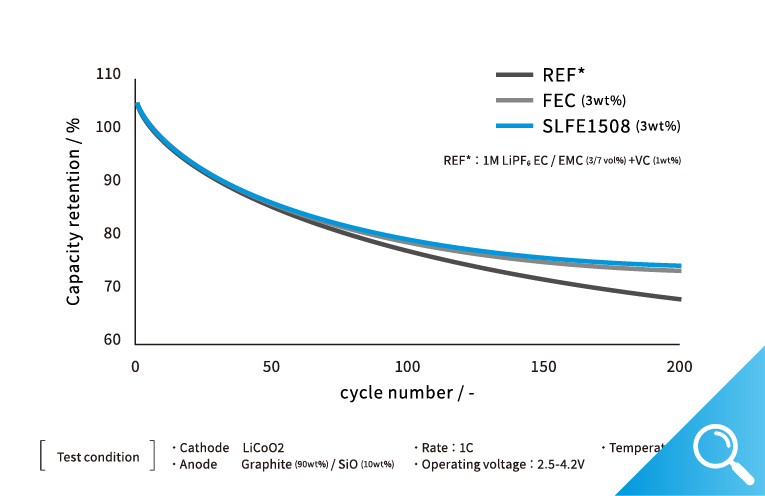

Excellent cycle life

SLFE1508 significantly improves the capacity reduction caused by the Si anode expansion and contraction, which is the same improvement effect as FEC.

Suppression of resistance increase

By suppressing the decomposition of the electrolyte,

SLFE1508 can suppress the resistance increase.

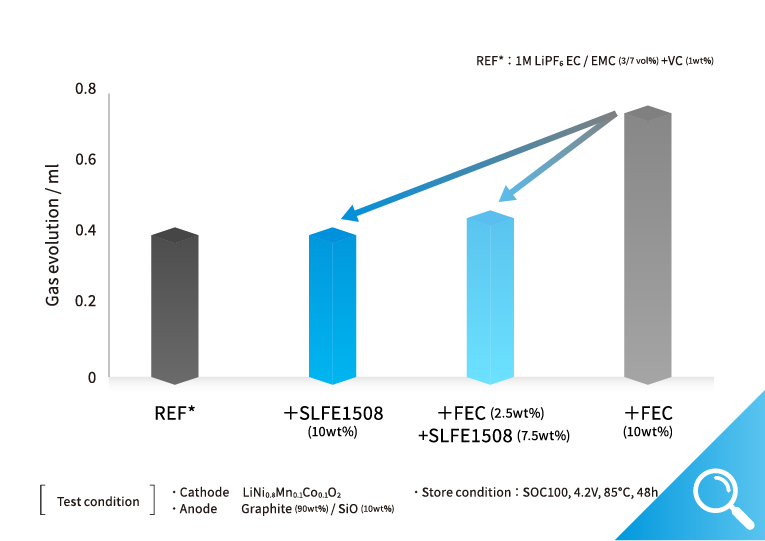

Suppression of gas generation

SLFE1508 has outstanding stable chemical stability compared to FEC which is a commonly used as anode additive.

SLFE1508 can reduce the gas generation while FEC generates decarboxylation gas.