![]()

Product information

02/2026

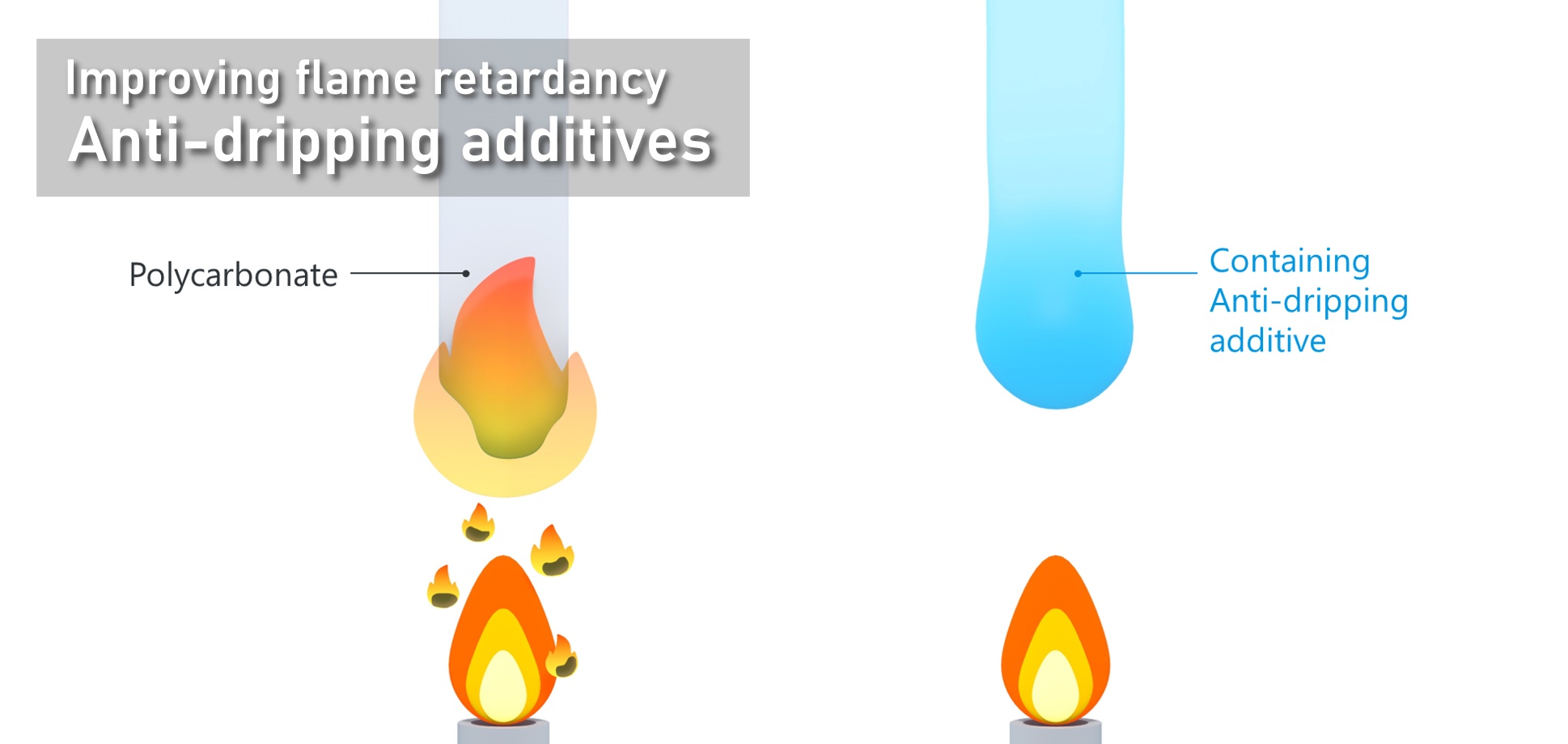

Improving flame retardancy

Fluoropolymer (PTFE) anti-dripping additives

Fluoropolymer PTFE exhibits a unique characteristic known as fibrillation (fiber formation). By utilizing this property, it can be used to enhance the flame retardancy of resins in combination with flame retardants. PTFE is used as an "anti-dripping additive" in electronics and office automation equipment. Furthermore, there is potential for using PTFE anti-dripping additives in fields requiring enhanced flame retardancy, such as automotive, construction, and data centers.

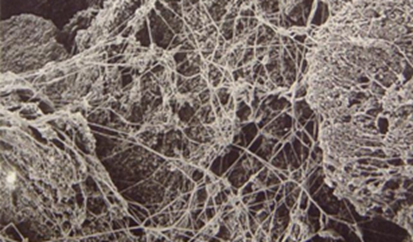

What is fibrillation of PTFE?

-

PTFE particles consist of multiple long fibers tangled together to form spherical particles. When subjected to shear forces, these particles transform into fibers and form a network structure. This rare character is known as fibrillation, a unique property of PTFE.

-

Fig. 1 Fibrillation structure of PTFE

Challenges in achieving flame retardancy

-

Resins that comply with flame retardant standards (UL standards) are widely used to prevent the fire in electronic appliances and OA devices. UL standards require that the resin does not drip while burning. However, it is difficult to completely prevent dripping with flame retardants alone, making anti-dripping properties essential

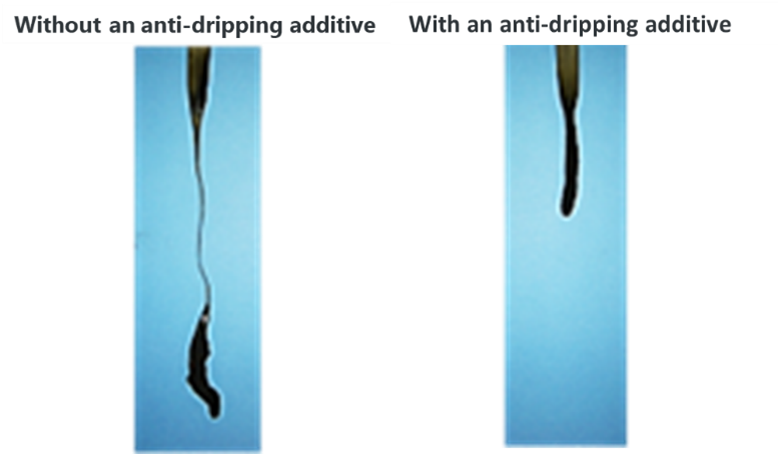

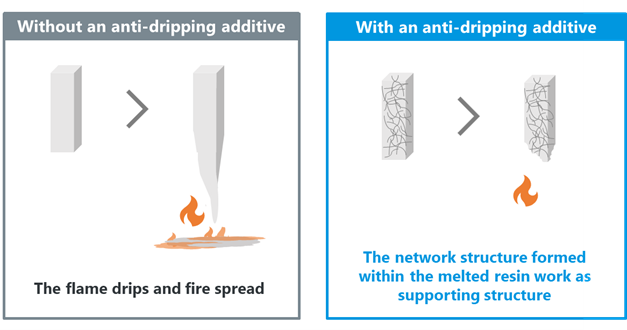

Mechanism of anti-dripping

PTFE-containing-mold demonstrates anti-dripping properties with an effective addition level of less than 0.5%. Generally, resins melt and drip when burned, causing the fire spread. However, by adding anti-dripping additives, PTFE within the resin forms a network structure that works as supporting structure to prevent the melted resin from dripping.

Fig. 2 Ignition combustion test with anti-dripping additive

Figure 3. Anti-dripping mechanism (Illustration)

Video 1 : Anti-dripping additives ignition and combustion experiment

Daikin's anti-dripping additives

-

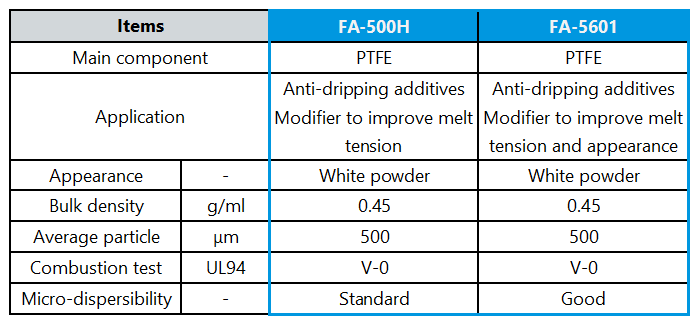

Two grades of anti-dripping additives are available.

Table 1. Daikin's anti-dripping additives

Expected applications

Our anti-dripping additives can be applied in various fields requiring flame retardancy.

- - Electronic appliance case

- OA case

- Construction materials

- Wire & cables

- Data centers (containment areas), etc.

Figure 4. Expected applications (example)

Please feel free to contact us with any questions or sample requests.

* The above physical properties are representative and not guaranteed.