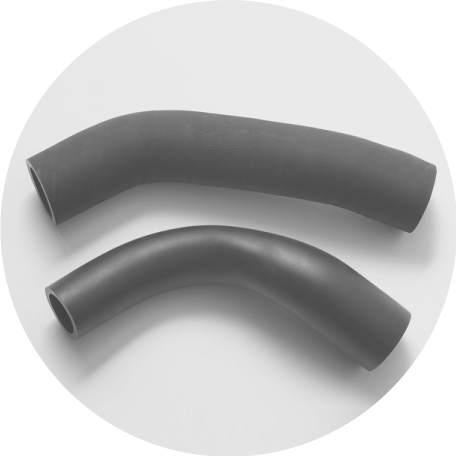

Tubes and Hoses

Piping materials such as valves, tubes, and hoses for automobile engines and chemical plants are designed with excellent chemical and heat resistance to safely carry harsh liquids and gases.

Daikin's Fluoroelastomer DAI-EL and Fluoropolymer NEOFLON deliver the safety and reliability necessary for these applications.

INDUSTRY TRENDS

With environmental regulations tightening and mixed fuels use increasing, the automotive industry is taking measures to reduce fuel permeation and exhaust gas emissions from internal combustion engines. In the semiconductor manufacturing and chemical processing industries, hose and tubing must meet strict performance requirements such as chemical resistance, heat resistance, and cleanliness.

Daikin solutions for meeting vehicle emissions standards include barrier materials to reduce fuel vapor permeation in multi-layer tubing and hose as well as heat and acid resistant elastomers used in exhaust gas recirculation systems. Daikin’s tubing materials provide the ultimate chemical resistance and cleanliness, which are critical to semiconductor manufacturing processes.

APPLICATIONS

Fuel hose / tube

The fuel hose / tube is connecting the fuel tank to the engine. Fluoro polymer and fluoro elastomer with low fuel permeability are used for this application.

Turbo charger hose

The turbocharger improves the heat efficiency of the internal combustion engine (ICE). Turbocharger hoses must function under high temperatures and high pressures, and high chemical resistance to acid as requested by exhaust recirculation (EGR). This demanding application uses fluoro materials in the inner hose layer.

Filler neck hose

The filler neck hose connects the fuel tank cap to the fuel tank. For this application, a fluoro polymer with excellent low fuel permeability is required.

![]()

Semiconductor manufacturing tubes and fittings

Materials for semiconductor manufacturing equipment require a high level of cleanliness, and excellent chemical and heat resistance.

Industrial tubing

Fluoropolymer tubing improves the safety and reliability of industrial equipment, such as heat exchangers and chemical transportation.