![]()

Under development material

09/2021

Fluoropolymer / carbon fiber composite

(under development)

Daikin's new developed "Fluoropolymer / carbon fiber composite" is a type of CFRTP (Carbon Fiber Reinforced Thermo Plastic) with excellent chemical resistance.

It is also expected to be used in various applications that require structural strength (mechanical characteristics), light weight, impact resistance, anti-smudge, water and oil repellency, slidability, flame resistance, and heat resistance.

Background of development

Daikin has been working on the development of a composite material with fluoropolymer and carbon fiber. This time, we succeeded in overcoming the challenge to improve mechanical properties without impairing the excellent features of fluoropolymer.

This new composite can be contributed to solve the following issues.

- Improve the mechanical strength of fluoropolymers

- Replace from the metal parts for the weight reduction

- Improve the characteristics of conventional Carbon Fiber Reinforced thermo setting Plastics (CFRP) such as impact resistance, anti-smudge, water and oil repellency, slidability, and flame resistance.

- Prevent the fluoro coating film falling off from the base material

Solution

- Downsizing and weight reduction by replacing from the metal parts (specific strength, toughness, heat resistance, low coefficient of linear expansion)

- Improve the properties by replacing from the thermosetting CFRP (chemical resistance, slidability, impact resistance, flame retardancy, anti-smudge)

- Improve moldability by chopped fiber (formability, reworkability)

Features

1. Support higher Vf*designs

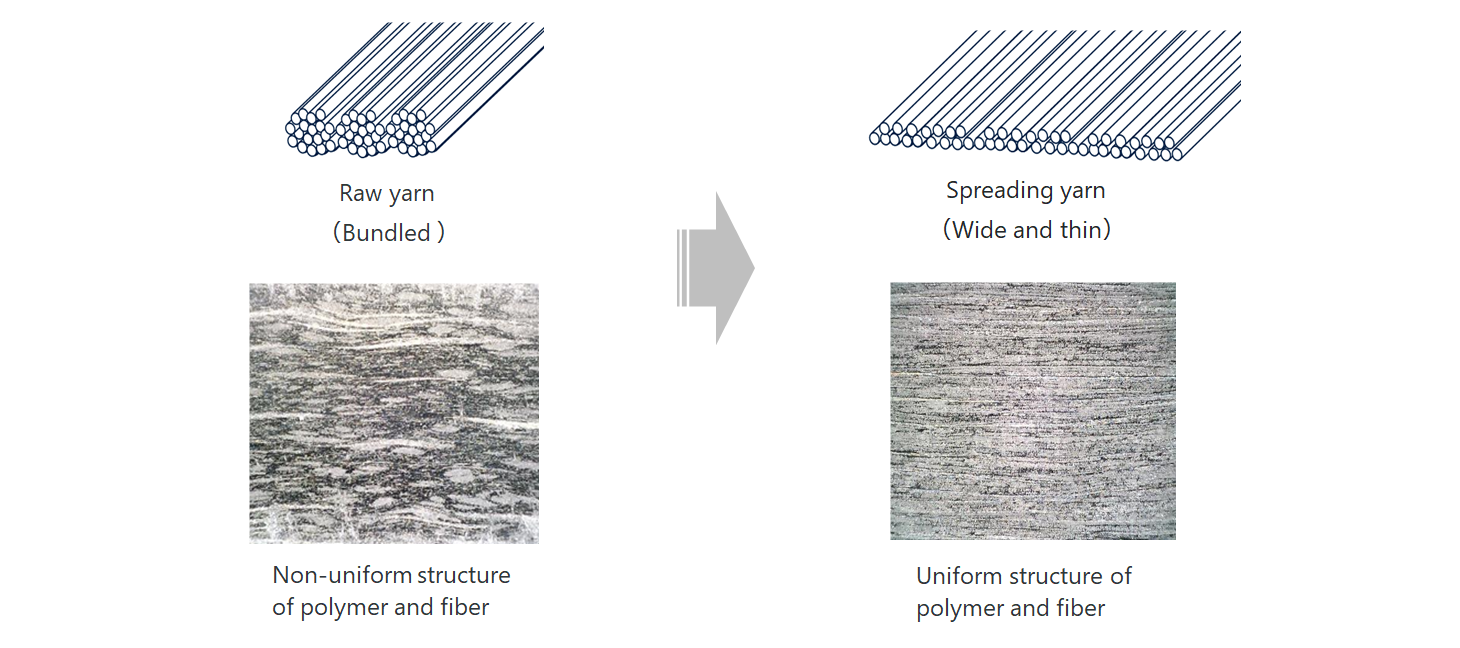

Due to the advanced carbon fiber spreading technology, it has excellent resin impregnation properties, and a dense laminated structure can be obtained even after molding.

It is possible to fabricate high impregnation, and higher Vf (over 50%). Therefore, higher strength can be expressed.

The uniform structure composite is resistant to delamination and improves the strength. (Fig.1)

Note* Vf : Fiber volume content

Fig.1 Carbon-fiber spreading technology

2. Contribut to weight reduction by replacement from metal parts

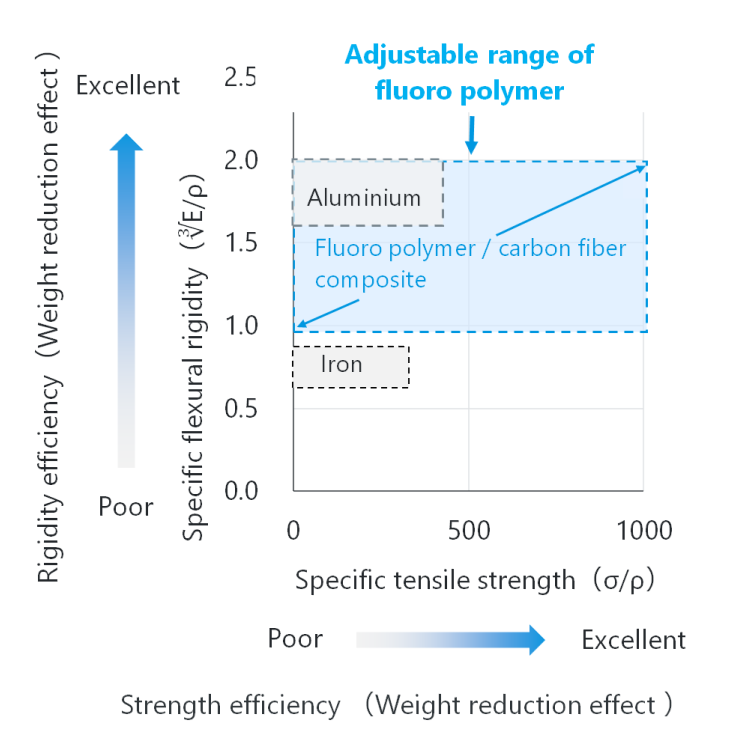

The composite of fluoropolymer and carbon fiber can be contributed to high specific tensile strength and specific flexural rigidity. With these advantages, it is possible to reduce the weight with the same strength compared with iron or aluminum.

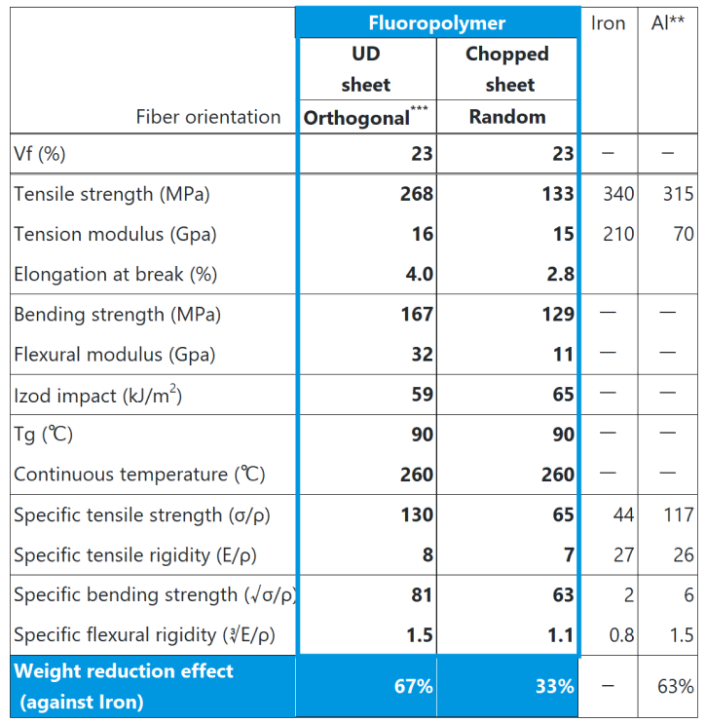

In case of the chopped sheet, it is expected to 33% weight reduction effect compared with iron.

Physical property such as specific tensile strength is just the example, then it can be further improved by carbon fiber content and fiber orientation.

Fig.2 Comparison of weight reduction effect

Table.1 Comparison data of mechanical properties

Note** Alminium

Note*** Laminated UD prepreg in the orthogonal direction

3. Excellent moldability and fluidity

Chopped sheets are randomly oriented prepregs made with carbon fiber shredded (chopped) in the length to keep high strength. Since chopped fibers flow with the melted polymer and filling up to the corner of mold, it is possible to suppress uneven strength of each part of the molded product.

4. Excellent acid resistance and alkaline resistance

5. Excellent impact resistance

Since the fracture toughness of fluoropolymer is kept even its composite with carbon fiber, it is harder to crack and has excellent impact resistance compared with conventional CFRP.

6. Excellent heat resistance

7. Excellent slipperiness due to the low friction surface

8. Excellent water and oil repellency, mud adhesion prevention and removal

9. Excellent frame retardancy

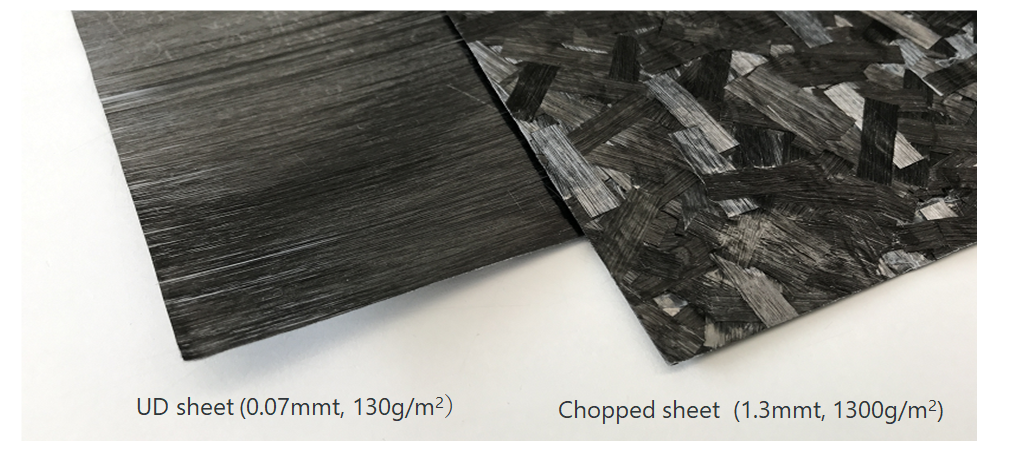

Assortment

The appearance of two types of composite sheets with different fiber orientations.

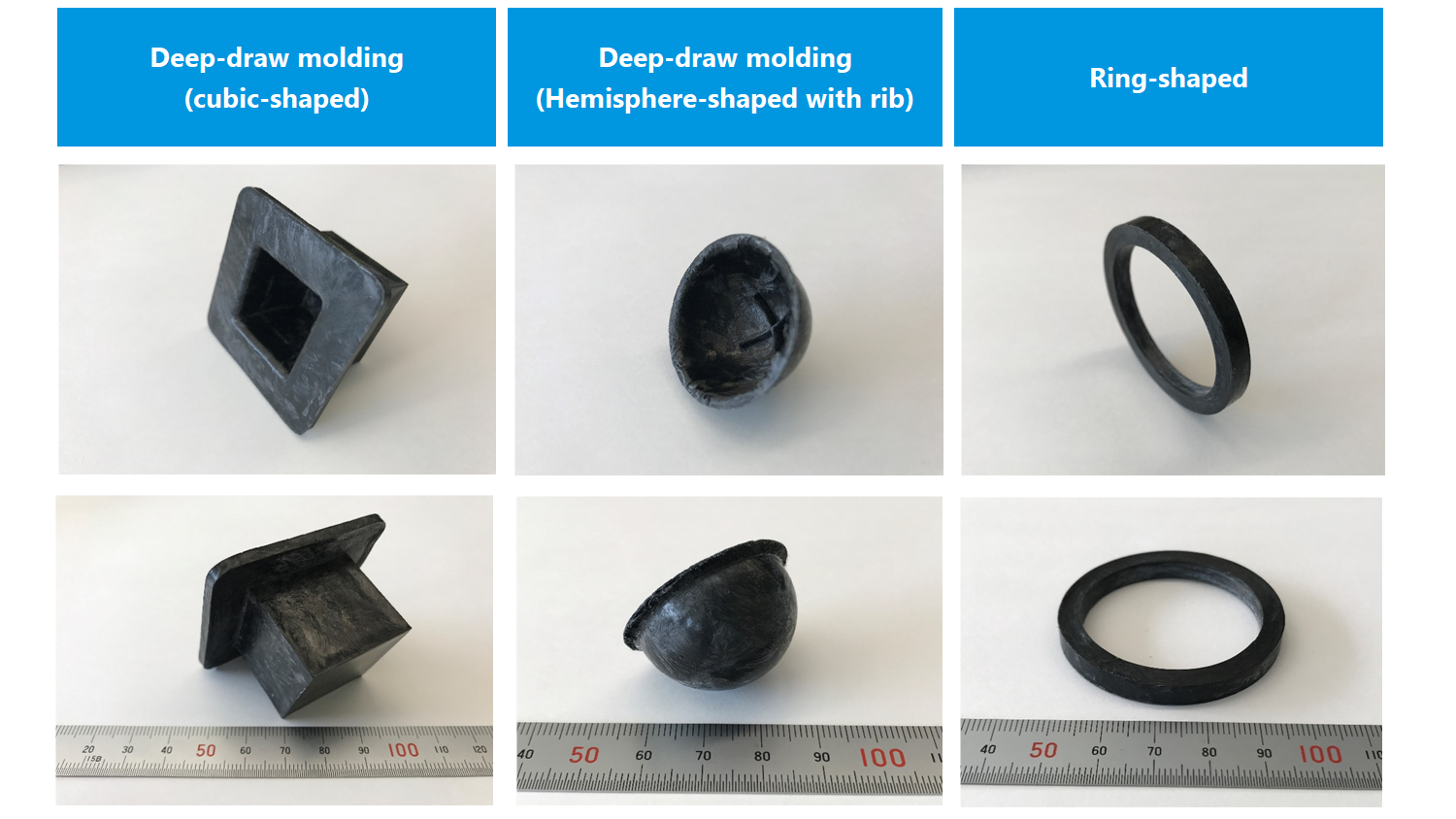

Examples of molding

Since chopped fiber is highly fluid, it can be molded into the following various shapes.

Expected industries and applications

- Robots, drones, aircraft, automobiles, oil and gas, marine structures that require weight reduction

- Semiconductors, life sciences, and food applications that require cleanliness

- Large structures that require extensive maintenance (offshore wind power generation, etc.)

- Alternative material for metal parts coated with fluoro paint

Please let us know your opinions and impressions about this product.

Note**** All the data shown in this report are not guaranteed.