![]()

Technical report

10/2022

The new opportunity of additive manufacturing with fluoropolymer PFA

Daikin has developed a fluoropolymer PFA which is suitable for additive manufacturing, powder bed fusion method (PBF method).

The fluoropolymer PFA, which is excellent in chemical and heat resistance and weatherability, is expected to be developed into semiconductors, medical applications, etc.

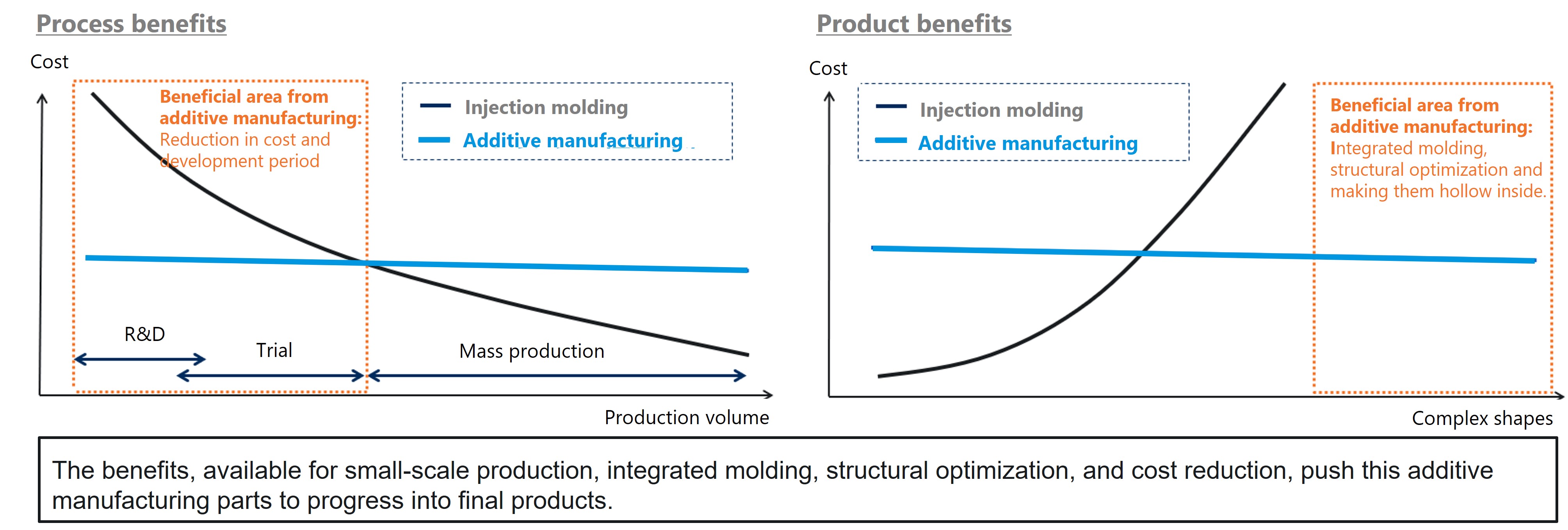

1. Trial and mass production cost reduced by additive manufacturing

A fluoropolymer PFA uses injection molding or extrusion as the common molding methods. Injection molding always needs dies to be fabricated whereas additive manufacturing does not. So, manufacturers can count on additive manufacturing to reduce costs in both trials and mass production.

・Trial production

Additive manufacturing is a die-free production method. Being capable of forming various shapes, this method helps to reduce trial production cost and time. Especially, there are greater cost benefits to the production of small volumes of prototypes.

・Mass production

Injection molding is advantageous cost-wise when producing the same product in high volume but is not suited to low-volume, high-variety production. In addition, even when producing the same product, it requires a post-process if a complex shape is involved. Therefore, additive manufacturing, which can mold any complex shape all at once, offers greater total cost benefits.

Fig.1 Process and product benefits from additive manufacturing

2. Performance of additive manufacturing moldings

The fluoropolymer has high temp. and low temp. resistance, weatherability, and chemical resistance. With these characteristics, additive manufacturing moldings of fluoropolymer have the same performance as conventional moldings.

・High and low temperature resistance

A fluoropolymer PFA can tolerate up to 260°C in continuous use. With this heat resistance, it is used in sealing materials, fittings, and valves for semiconductor manufacturing equipment. PFA, which tolerates not only high temp. but also low temp. as cold as an atmosphere of liquid nitrogen, allows for a broad range of applications at various temperatures.

・Weatherability

Acrylic and epoxy resins, which are widely used as materials for additive manufacturing, have weatherability issues to be addressed. The fluoropolymer, which has high weatherability, is suitable for outdoor applications as well. In fact, it is used as a material for the coatings of buildings in order to inhibit deterioration over time and as a tent coating.

・Chemical resistance

The fluoropolymer PFA has excellent chemical resistance to acids, alkalis, organic solvents, etc. For this reason, it is used for semiconductor manufacturing process applications in the majority of cases. PFA is a material that can be used in harsh environments that other materials would not be able to tolerate.

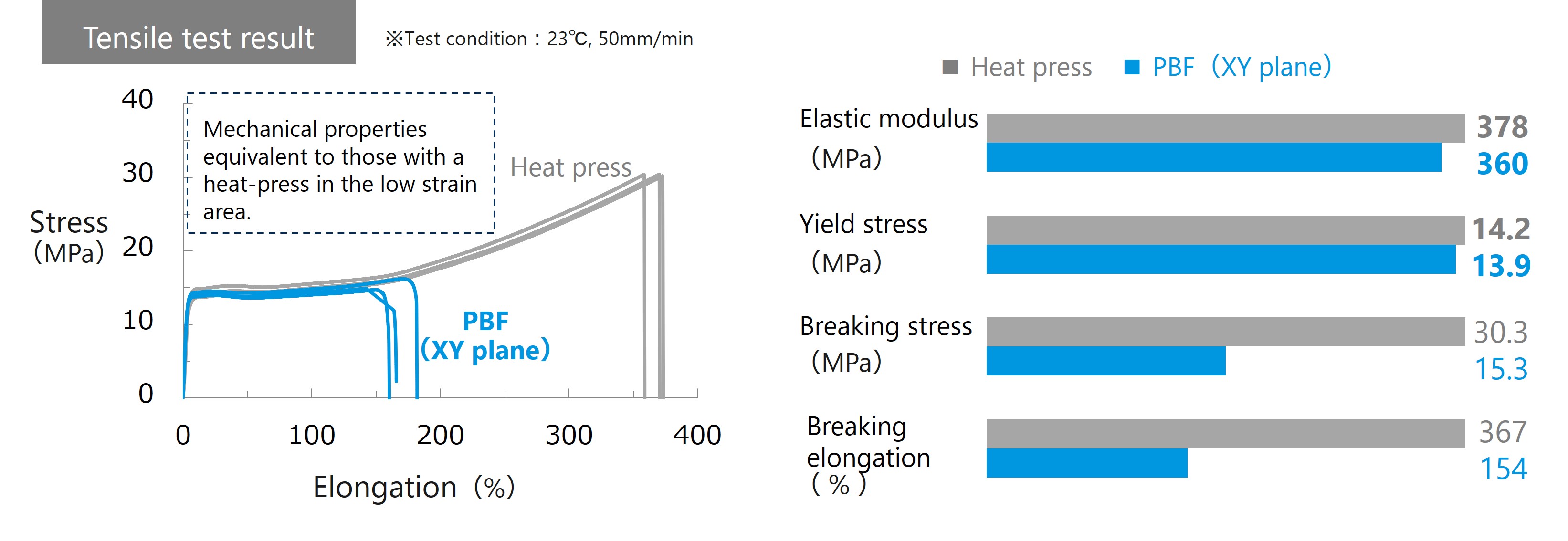

・Mechanical properties

Compared with the conventional moldings, the properties of additive manufacturing moldings are the same in the area where the breaking stress is 15 MPa or below and the breaking elongation is 150% or below, and in elastic modulus and yield stress.

Fig.2 Tensile test results of additive manufacturing and heat-press pieces

3. Potential for new applications has widened with fluoropolymer PFA

Daikin’s PFA powder for additive manufacturing, which is 100% pure, can make the most of the basic performance of PFA. Expecting to find applications in semiconductors, medical etc, Daikin is exploring additive manufacturing new opportunities that fluoropolymer PFA will open up.

*Note; This development product is intended for general industry, and therefore its adequacy and safety as a raw material for medical purposes cannot be guaranteed.

RELATED ARTICLES

Technical report

05/2021

Fluoropolymer PFA for powder bed fusion (under development)

Since high-performance materials for additive manufacturing have been developed, Daikin is developing powders for the powder bed fusion method, one of the additive manufacturing method, using fluoropolymers, a type of super engineering plastics, as raw materials. This article presents PFA powder, suitable for this method, and the physical properties of molds.