DAISAVE SS-110

DAISAVE "SS-110" are advanced fluorinated liquids designed for use as heat transfer fluids in chillers used in the semiconductor industry. They are also ideal as heat transfer media for heat pipes and heat pumps.

DESCRIPTION

Features

- Wide Operating Temperature Range: Capable of meeting diverse temperature control requirements.

- High Insulation and Stability: Ensures excellent compatibility with various equipment, facilities, and products.

- Low Viscosity and Thermal Stability: Offers superior thermal conductivity, enhancing heat transport efficiency.

- Environmentally Friendly: Zero ozone depletion potential (DP) and low global warming potential (GWP).

- Handling Performanc: No flash point, providing excellent handling properties.

Applications

Thermal Medium Solutions

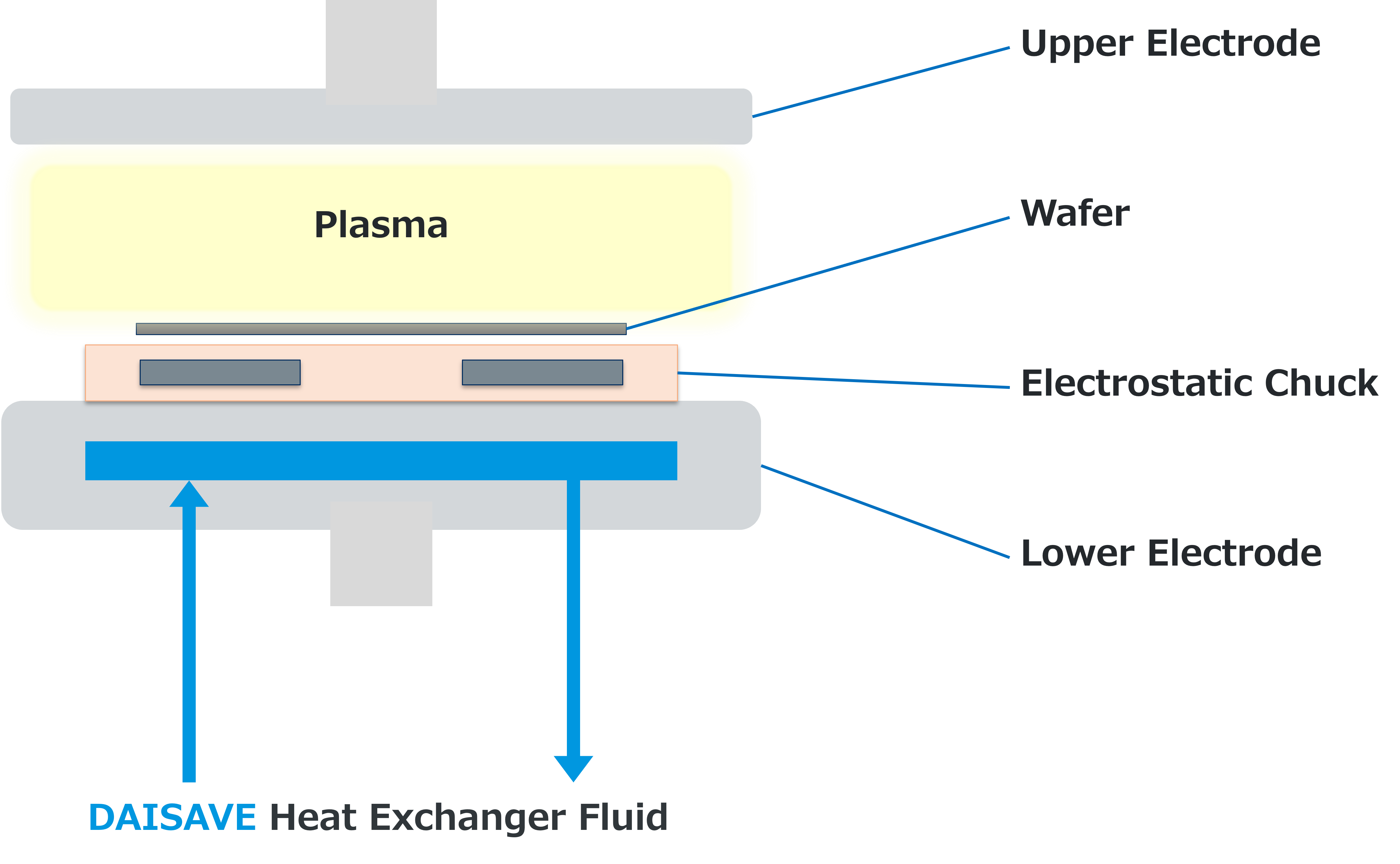

【Heat Transfer fluids for the Semiconductor Manufacturing Processes】

In semiconductor manufacturing processes such as etching, film deposition, and ion implantation, the demands for precise temperature control have become increasingly stringent due to the complexity and advancements in recent technologies.

These processes cover a wide range of temperatures, from extremely low to high, making fluorinated liquids a preferred choice as heat transfer media.

Key benefits include:

・A wide operating temperature range, high thermal conductivity, and excellent thermal stability to meet diverse temperature control requirements.

・High insulating properties that prevent electrochemical corrosion, enhancing the maintainability of equipment and installations.

・No flash point and easy to handle. These inert and chemically stable properties make them suitable for use in clean rooms.

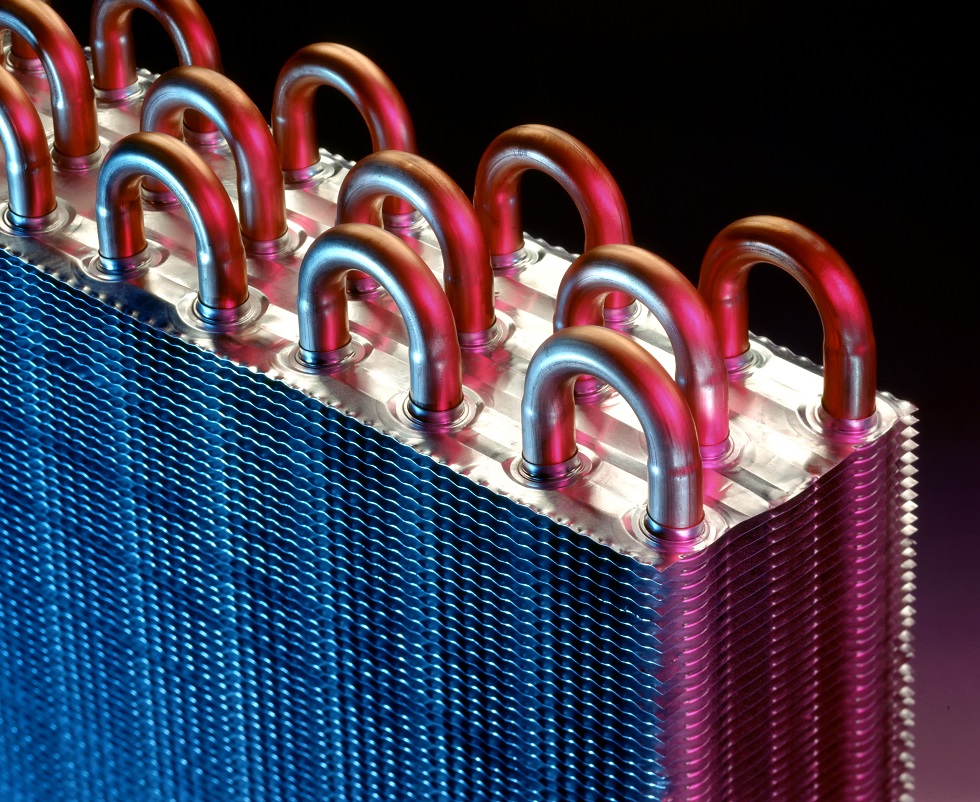

【Working Fluids for Heat Pipes and Heat Pumps】

Heat pipes, essential thermal conductivity elements used in various industrial and electrical appliances, require a working fluid with high heat transport capacity and low flow resistance.

Fluorinated liquids, known for their high stability and compatibility with common materials, are increasingly recognized as long-term working fluids.

Key advantages include:

・High density, resulting in high thermal conductivity per unit flow rate and excellent thermal stability.

・Low viscosity in both liquid and vapor phases, reducing the flow resistance of the working fluid.

・No flash point and high stability, ensuring compatibility with wick and container materials.

TECHNICAL DATA

Physical Properties

| Item Category | Item | SS-110 |

|---|---|---|

| Operating Temperature Range | Boiling Point [℃] | 110 |

| Freezing Point [℃] | <-130 | |

| Electrical Properties | Volume Resistivity [Ω・cm] | 1013 |

| Dielectric Constant | 2 | |

| Thermal Properties | Kinematic Viscosity [cSt] 25℃ | 0.95 |

| Thermal Conductivity [W⁄m・k] 25℃ | 0.064 | |

| Specific Heat [kJ⁄(kg・K)] 25℃ | 1.03 | |

| Density [g⁄cm3] 25℃ | 1.78 | |

| GWP |

<100 ※Calculated value |

|

Material Compatibility

| Plastics | ABS、AS, Epoxy glass, PA6, PA66, PBT, PC , PE, PET, PF, PMMA, POM, PP, PPE, PPS, PS, PVC, PTFE, FEP, PFA, ETFE, PVDF, ECTFE |

|---|---|

| Elastomers | Chloroprene rubber, Chlorosulfonated polyethylene rubber, Ethylene propylene diene monomer, rubber, Butyl rubber, Nitrile rubber, Natural rubber, Urethane rubber, Silicone rubber, Fluoro rubber(FKM) |

| Metals | Aluminum, Copper, Brass, SUS 304, SUS 316 |