NEOFLON ETFE EP-Series

NEOFLON ETFE EP-Series has the best mechanical strength and radiation-resistance among fluoropolymers. It is melt moldable and exhibits excellent processability and mechanical properties with great thermal, chemical and electrical properties. It is used for applications that require both mechanical strength and thermal, chemical, and electrical properties.

DESCRIPTION

Feature

- A copolymer of tetrafluoroethylene and ethylene consisting of carbon, hydrogen and fluorine atoms.

- It has the highest mechanical strength among fluororesins.

- It has the best radiation resistance among fluororesins.

- Flame retardant (limiting O2 index 31 vol% EP-500 system, 50 vol% EP-600 system).

- It is not attacked by acids, alkalis or organic solvents.

- This molecular structure has a low polarity and exhibits a low dielectric constant and a low dielectric loss tangent.

- Melt molding methods are available such as extrusion molding, injection molding and compression molding.

- It has higher melt fluidity than the other fluororesins and is suitable for high speed extrusion use.

Excellent characteristic

- Chemical resistance, permeability barrier

- Weatherability

- Electrical property

- Optical property

- Flame retardant

Applications

NEOFLON ETFE EP-Series has higher melt fluidity compared with the other fluoropolymers. It is designed for a variety of melt forming methods.

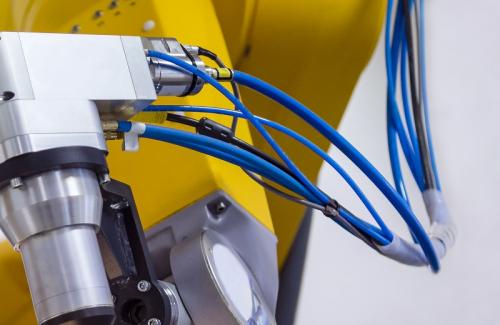

- Wire coating

- Electrical components (connectors, sockets)

- Fuel tube (low permeation)

- Mould releasing film

- Pipe lining

GRADES & FEATURES

| GRADES | DOWNLOADS |

|---|---|

| EP-521 | TECHNICAL DATA SHEET |

| EP-541 | TECHNICAL DATA SHEET |

| EP-610 | TECHNICAL DATA SHEET |

| EP-610AS | TECHNICAL DATA SHEET |

| EP-620 | TECHNICAL DATA SHEET |

| EP-620AS | TECHNICAL DATA SHEET |

| EP-7000 | TECHNICAL DATA SHEET |