POLYFLON PTFE Compound-Series

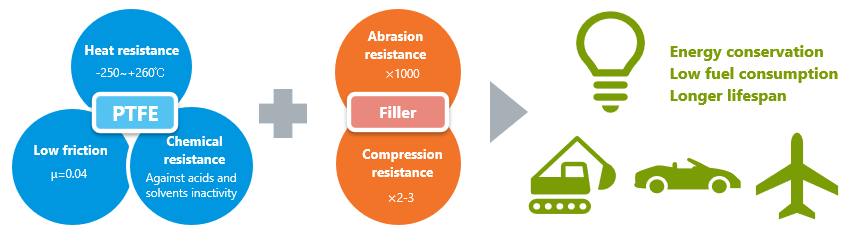

POLYFLON PTFE Compound-Series is a molding powder with a broad application range, made by blending molding powder POLYFLON PTFE and fillers, to improve the mechanical properties while maintaining the excellent properties of POLYFLON PTFE.

Depending on the molding method, fine or granular powder can be selected, as suitable for compression, automatic, or ram extrusion molding.

DESCRIPTION

Features

Made by blending molding powder POLYFLON PTFE and fillers, this new reinforced PTFE combines the superior properties of PTFE with the functionality of fillers. It has improved various mechanical properties, in particular abrasion resistance, compression resistance, and cold flow properties, with broad applications in various fields by taking advantage of POLYFLON PTFE, as being suitable for sealing materials, sliding materials, and piston rings.

Features of Daikin’s PTFE compound materials are summarized below:

- We offer more than 1,000 products of PTFE and fillers to more than 150 companies in 26 countries around the world.

- We provide high-quality products through consistent production and quality assurance systems from sourcing raw PTFE materials to blending them.

- We provide suitable products for each customer's application with our blending techology and flexible responsibness.

Applications

PTFE compounds take advantage of the mechanical properties and compression resistance of fillers to meet a variety of needs, mainly low friction and high durability. It is used in a wide range of applications including general industrial uses and automotive industries.

| Filler | Characteristics | Examaple of applications |

|---|---|---|

| Carbon fiber | Abrasion resistance and mechanical properties in oxygen atmosphere | Compressor piston ring |

|

Bronze |

Compression resistance in mechanical applications | |

|

Bronze / glass fiber / molybdenum disulfide |

Abrasion resistance, compression resistance, and creep resistance suitable for construction machinery | Hydraulic cylinder |

|

Carbon fiber (modified PTFE) |

Creep resistance in high-pressure applications | |

|

Glass fiber |

Abrasion resistance, chemical resistance, mechanical properties | Oil sealing |

|

Carbon / graphite |

Low wear and abrasion resistance suitable for high-speed applications |

-

In addition to the above, the following fillers can be combined:

- Glass beads or nano beads

- Carbon fiber (PAN- and pitch-based)

- Conductive filler (standard and food grade)

- PPS and modified PPS

- Polyimide and PEEK

- Hard carbon (coke) and soft carbon

- Graphite (special grade)

- Bronze (irregular, dendrite, or spherical) etc.

GRADES & FEATURES

We combine various grades of PTFE with a wide variety of fillers to create the best recipe for your needs.

Small lots are available, so please feel free to contact us.

Different applications are available for different molding methods:

- NFF (non-free-flowing: fine powder form): compression molding

- FF (free-flowing: granular form): compression, semi-automatic, or isostatic molding

- FF/HD (FF: granular form + high bulk density): compression or automatic molding

- E (pre-sintered form): ram extrusion molding

| Grade | Filler |

Filler amount |

Specific gravity |

Tensile strength (CD) |

Elongation (CD) |

Hardness |

Shrinkage rate |

Applications |

|---|---|---|---|---|---|---|---|---|

| - |

ASTM D4894 |

ASTM D4894 |

ASTM D4894 |

Needle type |

Internal method |

|||

| % |

- |

MPa |

% |

Shore D |

% |

|||

| (Reference) | Non-filler | - | 2.17 |

31 |

310 | 57 | 3.0 | - |

| 15GL | Glass fiber | 15 | 2.22 |

23 |

300 | 62 |

2.4 |

- Useful in a wide range of applications - Not suitable for soft metal parts unless dosage of glass is very low - Use in water may cause uneven abrasion |

|

25GL |

Glass fiber |

25 | 2.25 | 18 | 270 | 64 | 2.1 | |

|

25CAR |

Hard carbon (amorphous graphite) |

25 | 2.10 | Min.15 | Min.90 | 63 | 2.5 |

- Ideal for water applications and recommended for medium and high loads

- Compressor ring, V-ring, and packing |

|

25CAR/R |

Soft carbon (microcrystalline graphite) |

25 | 2.10 | 18 | 190 | 63 | 2.6 |

- Recommended for dry running with a low to moderate load - A wide variety of seals and bushings - Wear ring |

| 15GR | Graphite | 15 | 2.16 | 20 | 200 | 61 | 2.4 | - Piston band for shock absorber |

|

15GL5M |

Glass fiber |

15+5 | 2.26 | 20 | 260 | 62 | 2.5 |

- Dynamic seal - Lip-seal and shaft seal |

| 40BRR |

Amorphous bronze (antioxidation) |

40 | 3.08 | 26 | 270 | 65 | 2.2 |

- Recommended for hydraulic and pneumatic systems - Not suitable for water / insulation applications |

| 10CF |

Carbon fiber |

10 | 2.09 | 22 | 250 | 62 | 2.1 |

- Seal for power steering box (hydraulic pressure) - Sealing ring of high-pressure piston for compressor |

| 20CER | Ceramics | 20 | 2.03 | 18 | 200 | 62 | 5.5 |

- Alternative to glass and carbon fiber compounds |

| 10R |

PPS and cross-linked PPS |

10 | 2.05 | 22 | 260 | 59 | 3.0 |

- Self-lubricating bearing and sealing - Compressor ring and high-speed rotary radial seal - Backup ring and bushing - Packing set |

|

10RMOD * |

10 | 2.05 | 22 | 330 | 59 | 3.0 | ||

| 10PEEK | PEEK | 10 | 2.04 | 22 | 280 | 59 | 4.0 |

- Compressor ring and high-speed rotary radial seal - Backup ring and bushing -Packing set |

| 15RJ | Polyimide | 15 | 1.94 | 15 | 200 | 60 | 3.7 |

- Self-lubricated bearing, piston ring, and sealing element - Skived film and sheet |

| 10EK |

Aromatic polyester |

10 | 2.07 | 22 | 320 | 60 | 2.5 |

- High-speed rotary radial seal, self-lubrication, and slide bearing - Compressor ring, spring load seal, and bushing |

| 15KV | Aramid fiber | 15 | 1.98 | 13 | 200 | 60 | 2.5 |

The above numeric values are representative and not guaranteed.

*Based on modified PTFE

All compounds can also be formulated using a modified PTFE base.

-

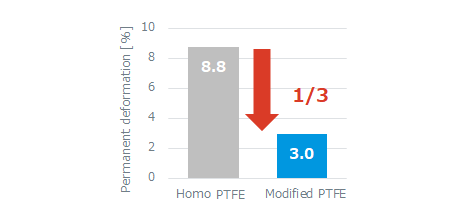

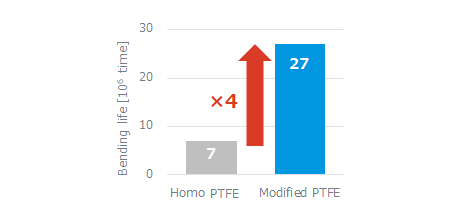

<What is modified PTFE?>

It is PTFE with added functions such as creep and flexure resistance, while keeping the heat and chemical resistance of the homotype.

Creep resistance of modified PTFE

- ASTM D 621 compliant

- 25 °C, -13.7 MPa

The above numeric values are representative and not guaranteed.

Flex resistance of modified PTFE

- MIT exam

- ASTM D2178 compliant

The above numeric values are representative and not guaranteed.