![]()

Article

09/2025

Fluoro materials for future of data centers

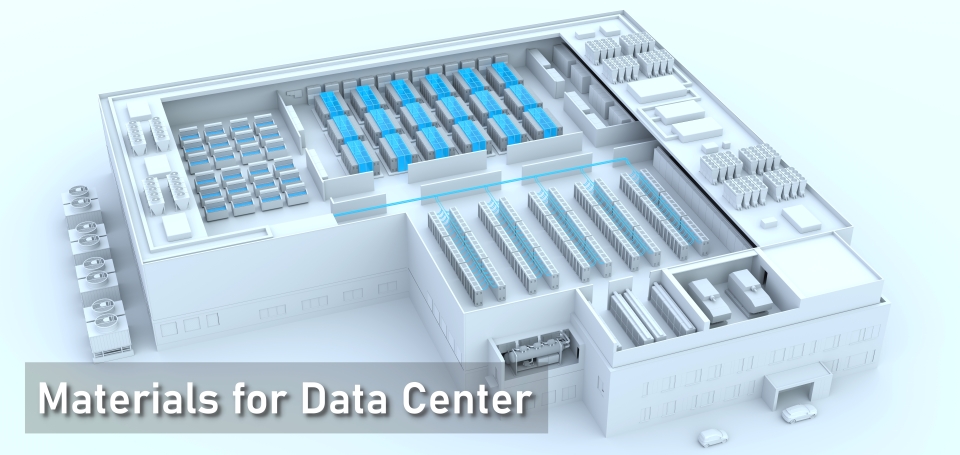

Data centers are a vital part of today’s information infrastructure. As AI usage increases, data transmission volumes also increase, leading to significant power consumption growth. Energy-saving solutions are urgently needed. Additionally, this information infrastructure requires enhanced cooling capacity for high heat semiconductor chips, faster communication, and increasing voltage levels. Daikin's advanced materials promise solutions for these demands and promote the evolution of data centers.

Daikin materials for data center

[Contents]

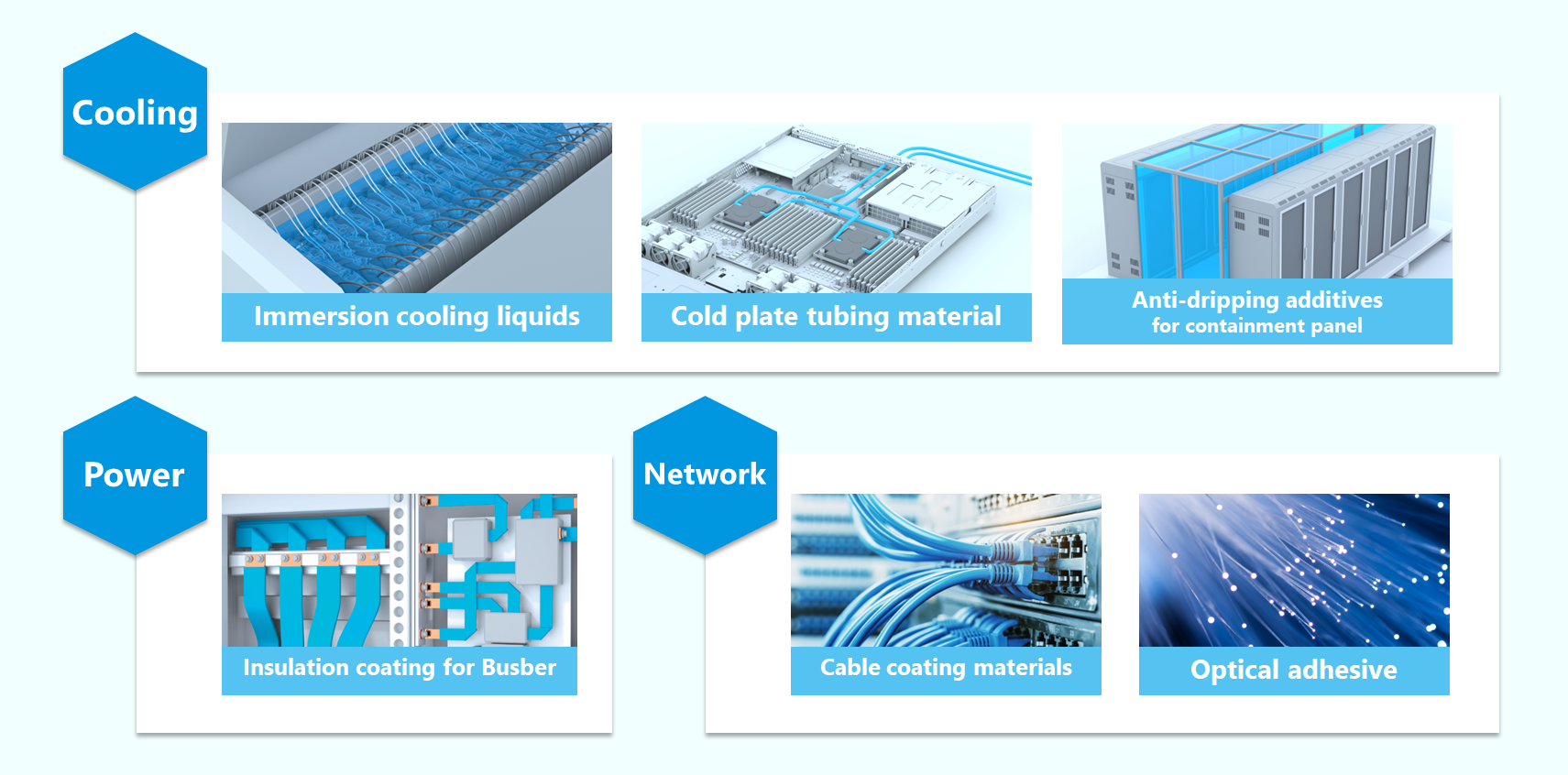

1. Cooling- Equipment and component materials

> 1-1. Fluorinated liquids DAISAVE for immersion cooling

> 1-2. Fluoropolymer for cold plate tubing

> 1-3. Anti-dripping additives for containment panel material

2. Power- Equipment and component materials

> 2-1. Fluoropolymer coatings for busbars

3. Communication- Equipment and component materials

> 3-1. Fluoropolymer FEP for communication cable coating materials

1. Cooling- Equipment and component materials

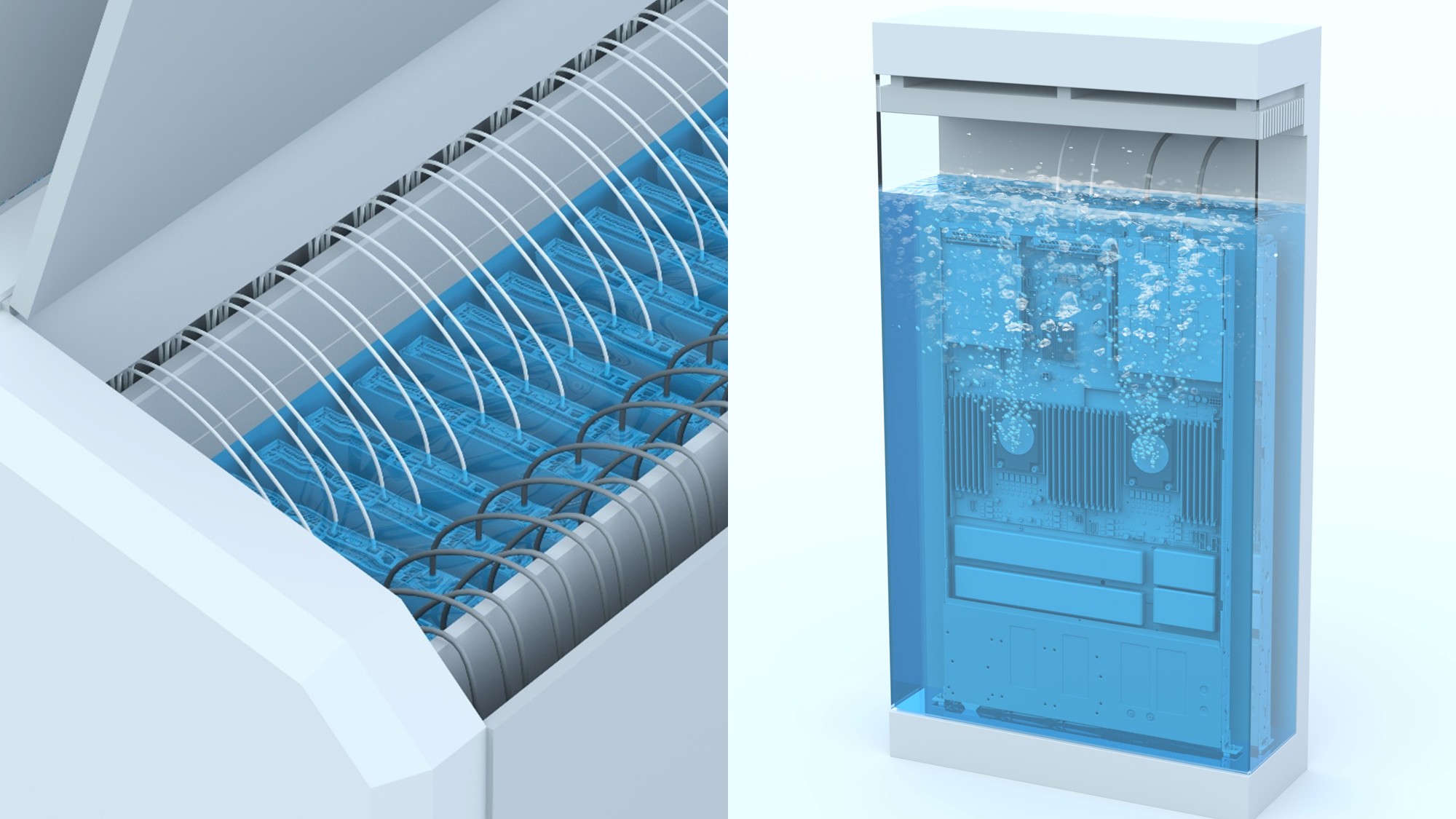

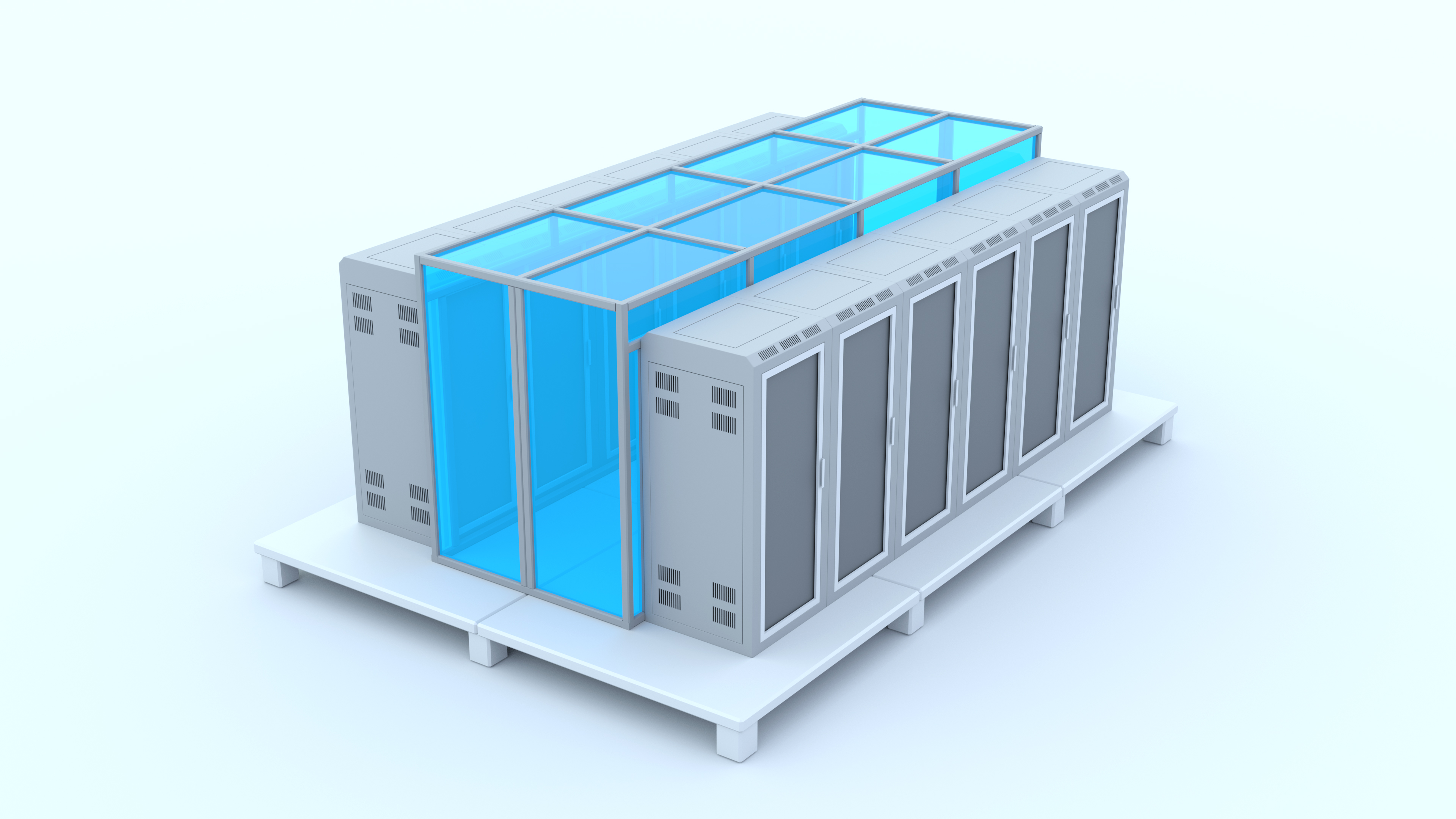

1-1. Fluorinated liquids DAISAVE for immersion cooling

Immersion cooling directly submerges servers in specialized liquids, significantly reducing power consumption as compared to traditional air- or water-cooling systems. Daikin's DAISAVE, as an immersion cooling liquid, is both highly thermally and chemically stable with low viscosity and excellent drying properties.

Related pages :

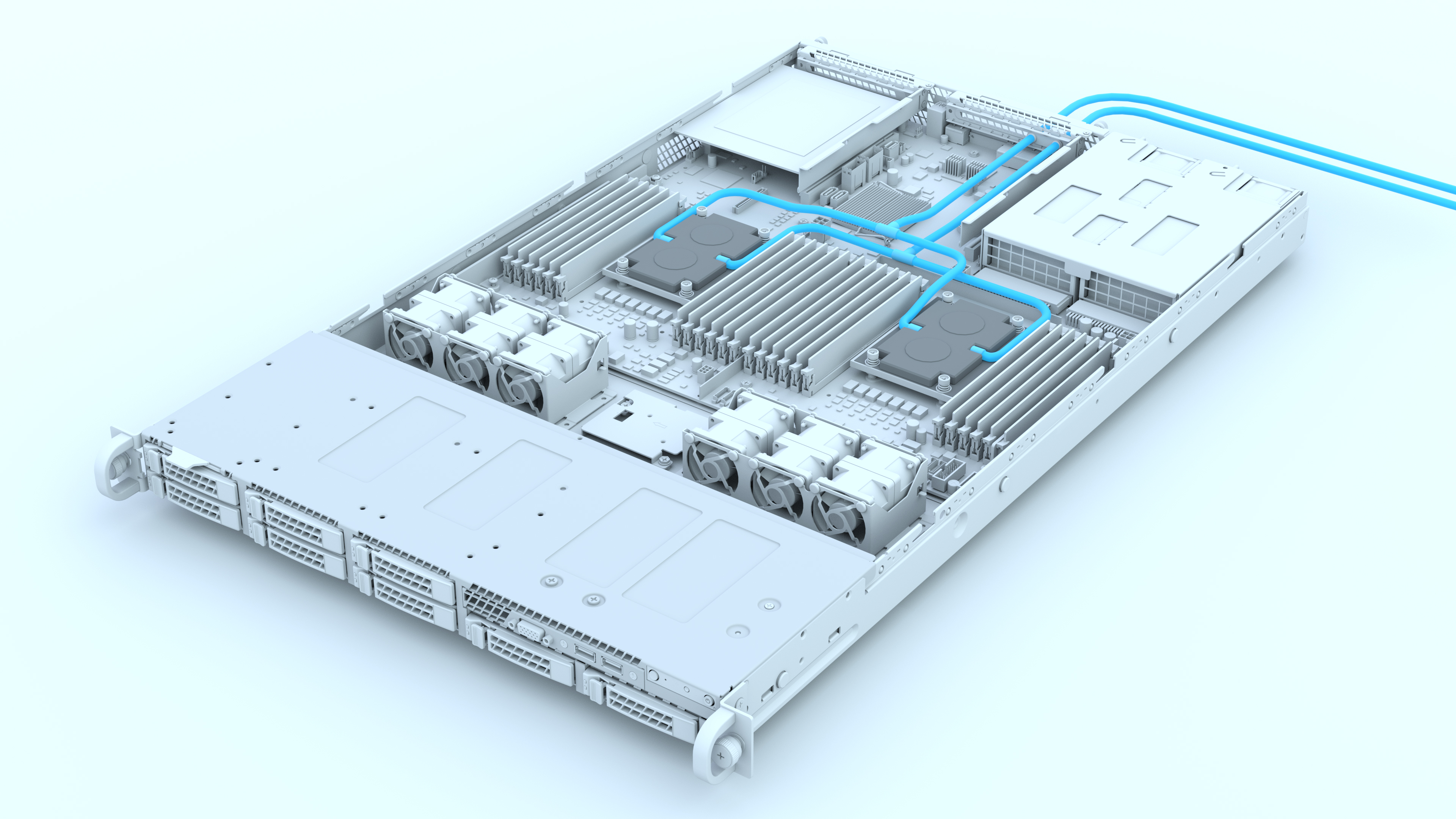

1-2. Fluoropolymer for cold plate tubing

With the high heat output of AI chips, water-cooled cold plates allow better thermal dissipation. Daikin’s fluoropolymer enhances moisture protection and improves the integration of cold plate tubes into densely packed server interiors.

Related pages :

1-3. Anti-dripping additives for containment panel material

Fire resistance is essential to protecting the critical information assets housed in data centers. Mixing fluorine-based materials with the current containment panel materials prevents resin from dripping during possible combustion events and helps reduce the risk of spreading flames.

Related pages :

2. Power- Equipment and component materials

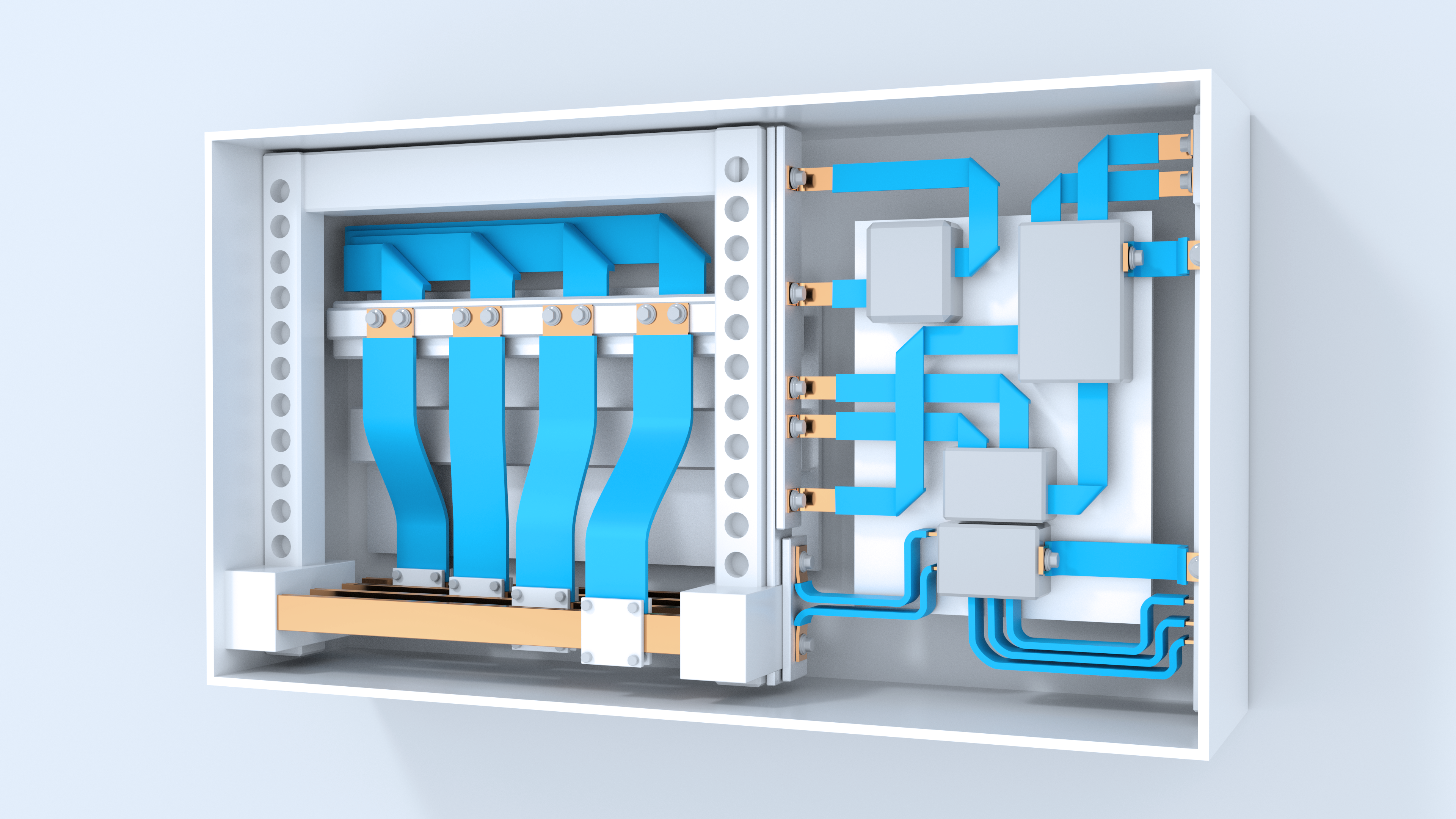

2-1. Fluoropolymer coatings for busbars

With the increasing power consumption of semiconductor chips and other electronic components, sever power supply busbars must be rated for higher and higher voltages. Fluoropolymer coatings, with their high heat resistance and insulator properties, enhance the safety of these high voltage busbars.

Related pages :

3. Communication- Equipment and component materials

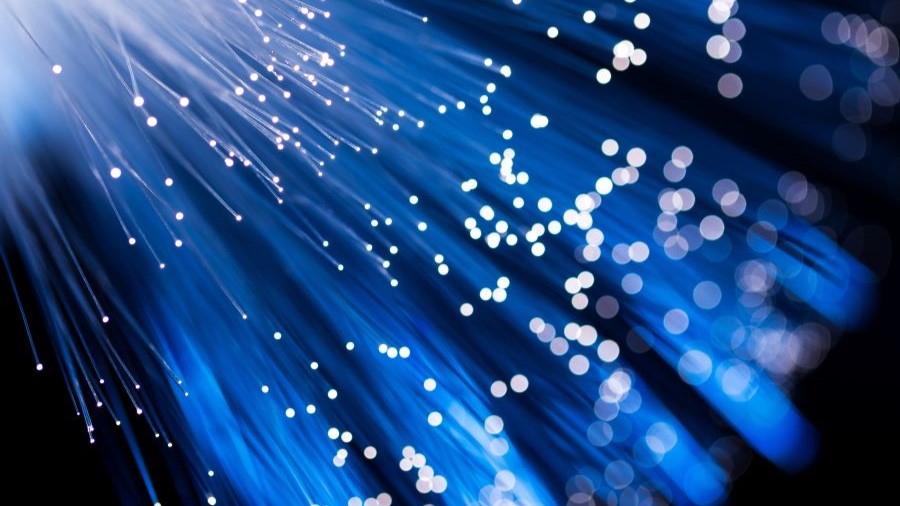

3-1. Fluoropolymer FEP for communication cable coating materials

Data centers require high communication speeds to handle the ever-increasing data transmission volume. Daikin’s FEP allows for low transmission loss and enables the miniaturization of communication cables, with its excellent high-frequency characteristics, dielectric characteristics, and molding processability.

Related pages :

3-2. OPTDYNE optical adhesive

Optical technology facilitates low energy consumption, high-capacity communication, and low-latency connections in data centers. This unique method requires matching refractive indices and durability in optical component adhesives. OPTDYNE optical adhesive produces reliable bonding strength and workability , enhancing optical technology materials.

Related pages :

Please feel free to contact us with any questions or sample requests.

RELATED PRODUCTS

Special website

09/2024

Low GWP Fluorinated liquid DAISAVE

DAISAVE series combines excellent thermal and chemical stability,

zero ozone depletion potential, low surface tension, low viscosity, good solubility, and the drying properties necessary for effective cleaning.