Powertrain

Fluoropolymer coated wires and cables are used in automotive powertrain systems, attached to transmissions and motors. In the harsh, under-hood operating environment insulation, high temperature characteristics, and excellent oil resistance are key. Additionally, with the shift to electrification, excellent dielectric properties are also necessary.

Axle seal・Transmission seal

Required characteristics

- Transmission oil resistance at high temperatures

- Flexibility at low temperatures

Daikin Solutions

Daikin’s DAI-EL Base Resistant Elastomers have heat and the fuel oil resistance unique to Fluoro elastomers. Moreover, it has excellent resistance to transmission oils. Used as a sealant inside axles and transmissions, it exhibits outstanding compression set at high to low temperatures.

Transmission cable covers

Required characteristics

- Heat resistance

- Dielectric properties

- Electric insulation

Daikin Solutions

When used as a wire cover material in transmission systems, Daikin’s Fluoropolymer NEOFLON FEP NP-Series and NEOFLON ETFE EP-Series have excellent heat resistance and excellent dielectric properties, low dielectric constant, and a low dielectric tangent.

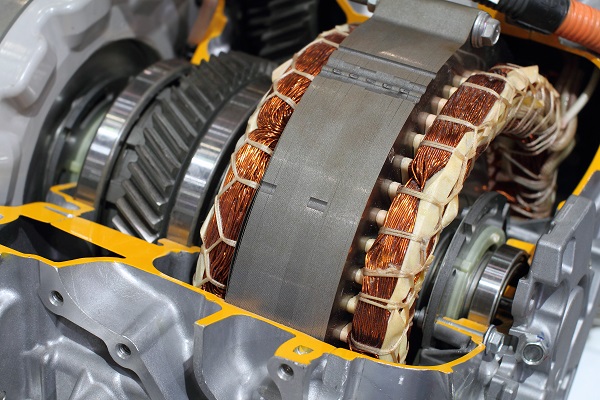

Motor seal material

Required characteristics

- Heat resistance

- Engine oil resistance

- Transmission oil resistance

- Low compression set

- Low temperature brittleness resistance

Daikin Solutions

Fluoropolymer and Fluoro elastomer are used in various Electric Vehicle applications as seal materials for motors. Fluoropolymer and Fluoroelastomer are used in various Electric Vehicle applications as seal materials for motors. Daikin’s Fluoro elastomer DAI-EL and Fluoropolymer POLYFLON PTFE M-Series are commonly used in bearing seals.

Coating material for motor windings

Required characteristics

- Dielectric properties

- Heat resistance

- Oil resistance

- High dielectric breakdown voltage

Daikin Solutions

Higher voltage, smaller next generation drive motors for electric vehicles are under development. Motor winding coating materials must have not only excellent dielectric properties such as a low dielectric constant and a low dielectric tangent, but also exhibit heat resistance, oil resistance, and high dielectric breakdown voltage. Fluoropolymer paint and coating materials meet these demanding requirements.